Page 19 of 22

Posted: Sat Jun 29, 2013 6:26 pm

Author: Magnum1

Proper nice Zed

Posted: Sat Jun 29, 2013 8:07 pm

Author: Rich

catch tank - need to lower the hose under the height of the tank in/out to get the oil to drop down into the engine. Looks a bit high on the bend

Posted: Sat Jun 29, 2013 8:46 pm

Author: LondonZ1

Rich, agreed, I thought that too but I'm going to wait until I see it in the flesh. I am sure Steve knows that oil flows downhill under gravity so maybe the hose wasn't connected to the breather when the photo was taken. The tank and hose were a last minute change (i.e. recognition of my design fault) and the hose has to clear the starter cables and carb bellmouths, which restricts the routing options. As long as the tank doesn't accumulate a significant proportion of the engine oil, I'm happy.

cylinder head

Posted: Sat Jun 29, 2013 9:38 pm

Author: buzzard

LondonZ1, what I don't get is you had your cylinder head refurbished by BLR Engineering, New guides, seat recut, 3 angles I presume as BLR use Serdi machines to do cylinder heads, so why did the cylinder head needed to be done again by Debben with a "more modern seat cut" what happened there? Buzzard.

Posted: Sun Jun 30, 2013 6:24 am

Author: LondonZ1

Buzzard, I asked BLR just to refurbish the head which they did. When Debben rebuilt the engine, Steve said that the standard valve seat was an inefficient design and that recutting the seat to a more complex shape would improve The gas flow. He also suggested fitting new valves as they old ones were worn. The cost was fairly modest so I said yes. Debben said that the valve guides and helicoiled plug thread (which BLR had done) were OK.

With hindsight I should have just shipped the motor down to Debben in the first place. BLR work on all sorts of car and bike engines whereas Debben specialise in older Kawasakis. One of the lessons of the project was that it's best to use specialists with directly relevant experience. They are often no more expensive and overall you get a better job. BLR were very helpful for me as I really needed a local engineering company for general machining and assistance so I would happily use them again for other jobs.

BLR

Posted: Mon Jul 01, 2013 7:42 am

Author: buzzard

Londonz1, I was just wondering what BLR were like as I have a machining job I can't do myself so it was a general enquiry, are they ok to deal with. Buzzard.

Posted: Mon Jul 01, 2013 1:38 pm

Author: LondonZ1

Depends on what you want done. BLR are generally excellent but they aren't cheap (£65 per hr from memory). For simple machining jobs I have been using Tim Hunt in Wales. I send Tim a sketch and he makes all sorts of bits for very reasonable prices. He made my dash, the instrument cans, the indicator stalks, headlamp spacers, oil cooler brackets, stuff like that.

I used BLR for more complex jobs where I needed to be able to meet the person and explain exactly what I wanted, e.g front wheel spindle, rear caliper hanger mods, exhaust flange mods, removal of broken studs etc. Russell is very friendly and knowledgeable.

new mmber

Posted: Mon Jul 01, 2013 1:58 pm

Author: FOZ1A

BLR did my head last year, new guides and seats cut to suit oversize valves, gas flowed and ported £500. These guys know their stuff and turned it round in 2 weeks.

foz

Posted: Tue Jul 02, 2013 3:41 pm

Author: LondonZ1

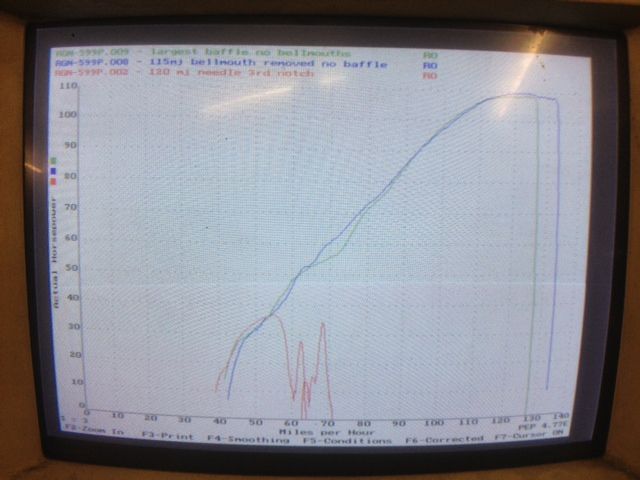

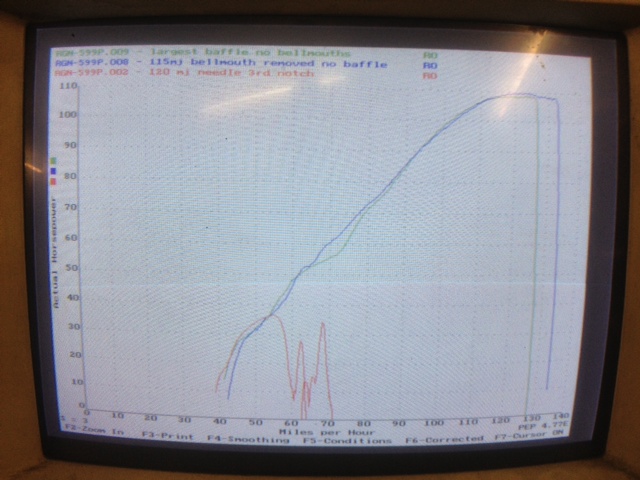

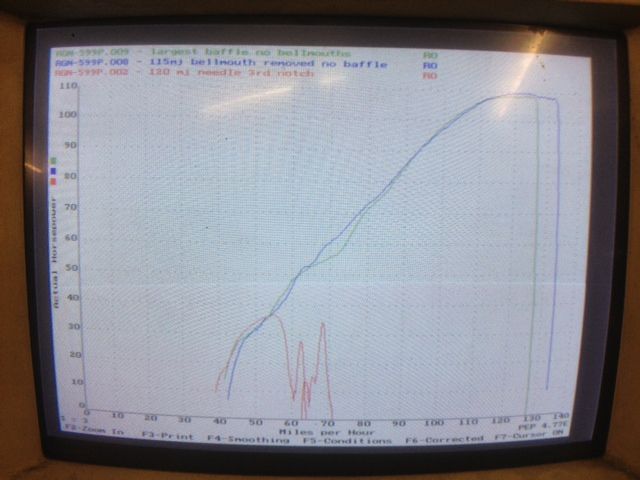

- 110bhp.jpg (111.96 KiB) Viewed 26303 times

Bike finally made it onto the dyno today and Steve Debben emailed me a pic of the dyno screen. It's a nice straight line so the bike should be easy to ride. It made 105hp peak power at the rear wheel which I am really pleased with, I was hoping for 90-100. Steve is going to try smaller mains (115) and he thinks that the gearing is too tall, max power is at 125mph in 4th. The speed sensor is mounted in the rear disc so changing sprockets won't affect the speedo reading.

Posted: Tue Jul 02, 2013 6:31 pm

Author: j.wilson

Seen the bike in the flesh- its really nice- long, low and the colour is really perfect.

Difficult to find fault with it...

but I think......

hmmm, I told you- nothing to change its great..

In fact its an inspiration.

Posted: Tue Jul 02, 2013 7:12 pm

Author: morten

LondonZ1 wrote:Rich, agreed, I thought that too but I'm going to wait until I see it in the flesh. I am sure Steve knows that oil flows downhill under gravity so maybe the hose wasn't connected to the breather when the photo was taken. The tank and hose were a last minute change (i.e. recognition of my design fault) and the hose has to clear the starter cables and carb bellmouths, which restricts the routing options. As long as the tank doesn't accumulate a significant proportion of the engine oil, I'm happy.

Very nice Z !! With all respect, I dont think you should put the stuff collected in the catchtank back in the engine again! Just drain it once in a while and throw the stuff away!

It,s no longer usable oil but a very suspicious fluid

Posted: Wed Jul 03, 2013 6:25 am

Author: Pigford

Thats a brilliant power curve..........

ENJOY

Posted: Wed Jul 03, 2013 9:11 pm

Author: LondonZ1

Well there's good news and not so good news. The good news is that Steve has now extracted 110bhp, which I think is quite impressive for a mildly tuned 1015cc motor. The line is now even straighter which implies great midrange and good top end power, the ideal combination.

The not so good news is that the bike runs best with no baffles (very loud) but at least the loudest baffle only makes a small dent in the midrange, see chart.

The other not so good news is that it turns out that my expensive and beautifully made Japanese bellmouths are actually crap when it comes to airflow. Steve reckons that the bellmouths are too narrow at the front which mean that the pilot holes sit outside the mouth in still air, not inside the mouth where they benefit form better airflow. So, the bike runs better with open carbs and no bellmouths.

I am not sure how to fix this as I do want to have some form of filters. I am thinking of getting some simple alloy tubes made which fit round the outside of the carb inlets (so the pilot holes are inside the tubes) and to which I can attach the original S&S filters. This should enable me to package the filters behind the bulge in the side panels, keeping the current looks but having a glitch-free midrange and having filters all at the same time. Option 2 is to have tubes made with a flared end that will take the current gauze filters. I won't know for sure until I get the bike back and take some measurements. Oh, and Debbens have finished with the bike and I can now have it back as a fully functional motorbike. I just need to arrange collection (and pay a large but not unreasonable bill). I'll post some pics of the finished bike when it get it back. Can't wait!

Posted: Wed Jul 03, 2013 10:15 pm

Author: j.wilson

Hmm, don't be discouraged.

1) the baffle could be simply a perforated tube wrapped with wadding. It would take the edge off the sound and not be restrictive.

2)K&N filters have "bell mouths" in them made of rubber. I'd think about fitting them to see if you can get it to carb properly. If so, get some aluminium copies.

You just need a set-up that works and then adapt to them to get the look you want. You might just think hard about modding your bell mouths- perhaps you can have them cut down (to get the right diameter) then have some new cuffs soldered onto them to get the right mount to the carbs.

Posted: Thu Jul 04, 2013 5:30 pm

Author: neilbarrett

id get the bike back and ride it and see what you think

you might swap the baffles for quieter ones and not even notice the power loss on the road,did you get the bike dynod before and after the work had been done