Progress has been slower than I would have liked. There has been a huge amount of time taken wire wheeling and bead blasting.nine parts of the fasteners on this bike are black. Normally I replace a whole heap of fasteners with stainless with I tend to machine and polish, but SS has been kept to a minimum on this bike as there's no straight forward way to make it black.

Some may argue that plating the studs isn't necessary, and in truth it's probably a bit OTT, but they were plated originally, though I don't think mr Kawasaki passivated them black

Lots of time spent 'wiring up' parts

With the new nickel/zinc system I made up stainless hangers for the anodes so they can be easily removed and 'unplugged'. Because of the nature of the soup you have to remove the anodes as soon as the cooking is completed or the nickel anode plates the zincs and then they're no good.

Once passivated, the items have to be hung, like pheasants, to cure for at least 24 hours.

There have been many hours spent blasting in the bead blast cabinet

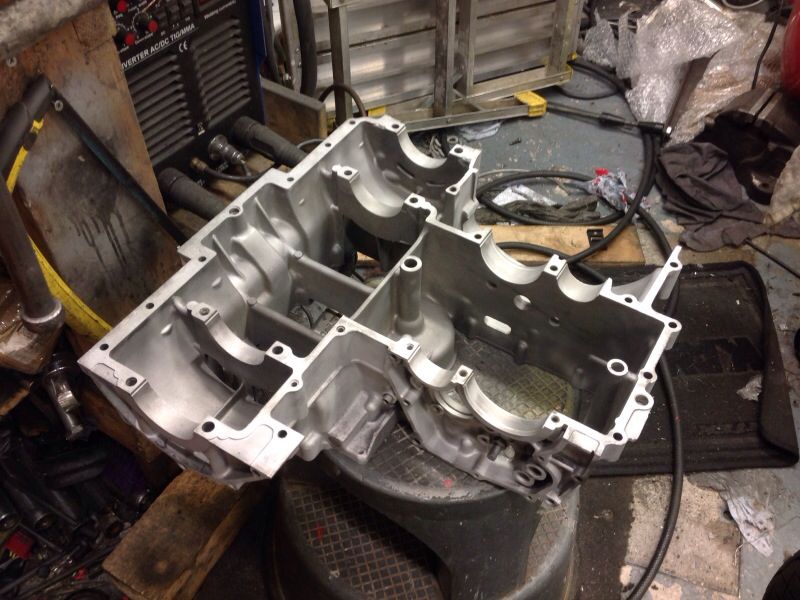

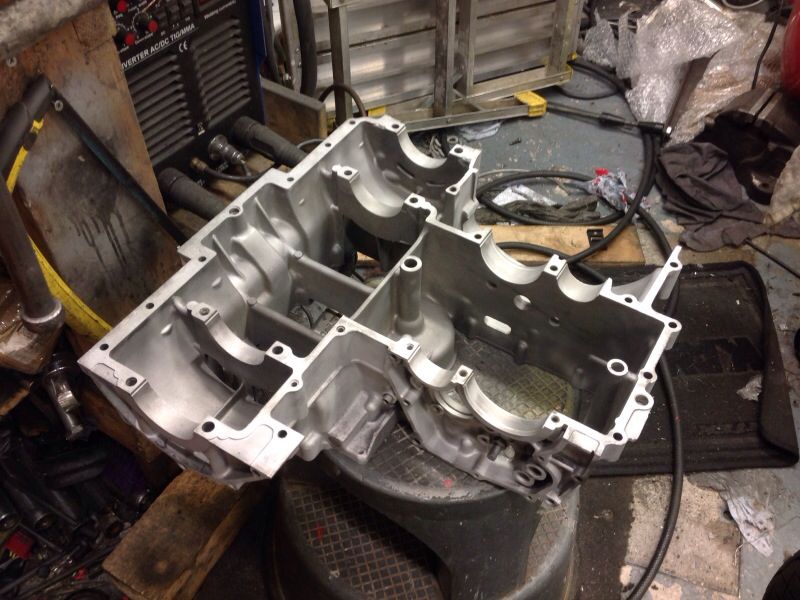

I've blasted all the casings apart from the head as that is a right royal pain in the the Gary Glitter to safely mask up due to the blind oil ways.

I had a paint session in the back garden where I did much of the mild steel parts that are in gloss black. I only used standard two pack etch, as none will be coming into contact with petrol or heat and it needed using up. I can't find the camera, so I'm not sure if I took any pix of that or not.

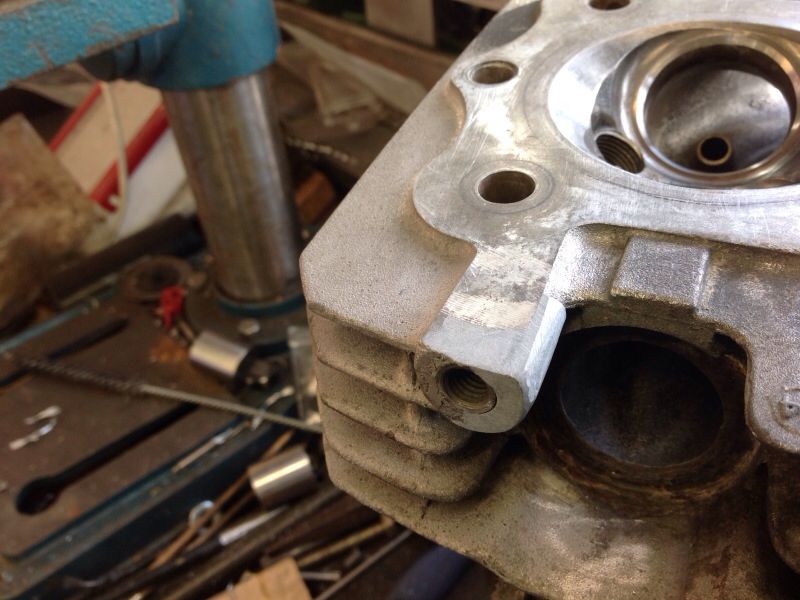

I did a bit more work on the head today ... More hours with the wire wheel on the Dremmel

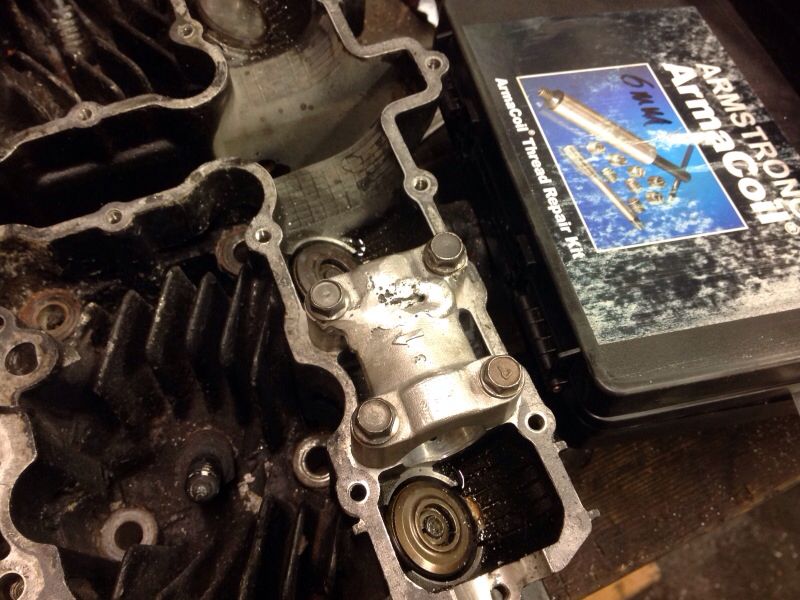

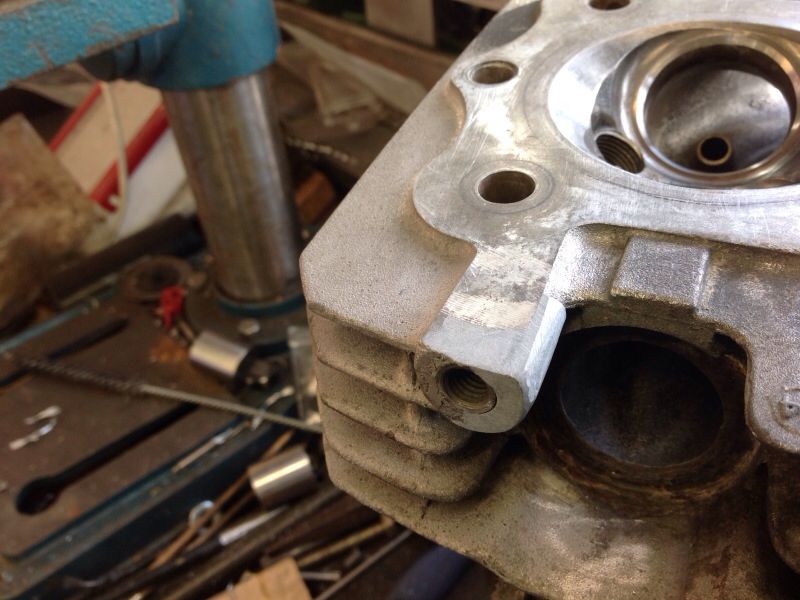

one of the exhaust studs had been bodged with a bit of studding, so I hacked out what was there and fitted a very long timesert, which I bedded in with BondLok epoxy aluminium putty stuff. It's not quite straight, but it's better that it was.

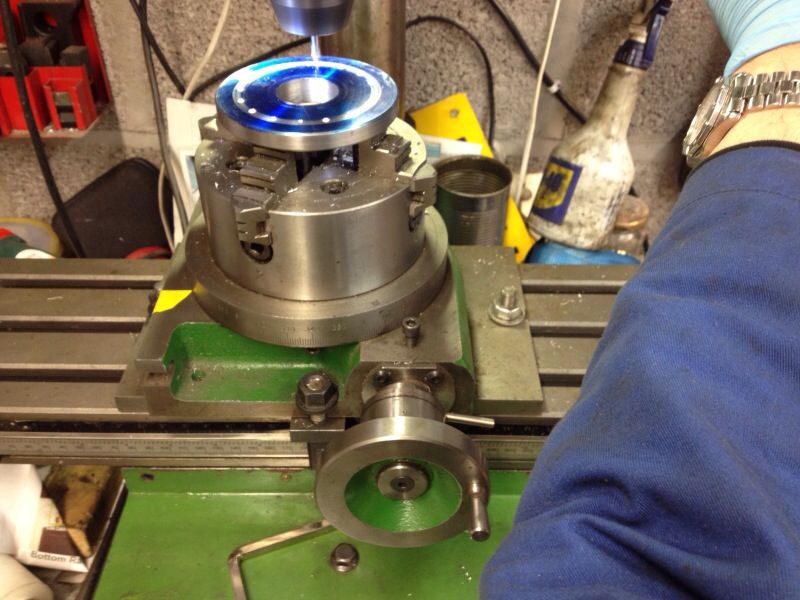

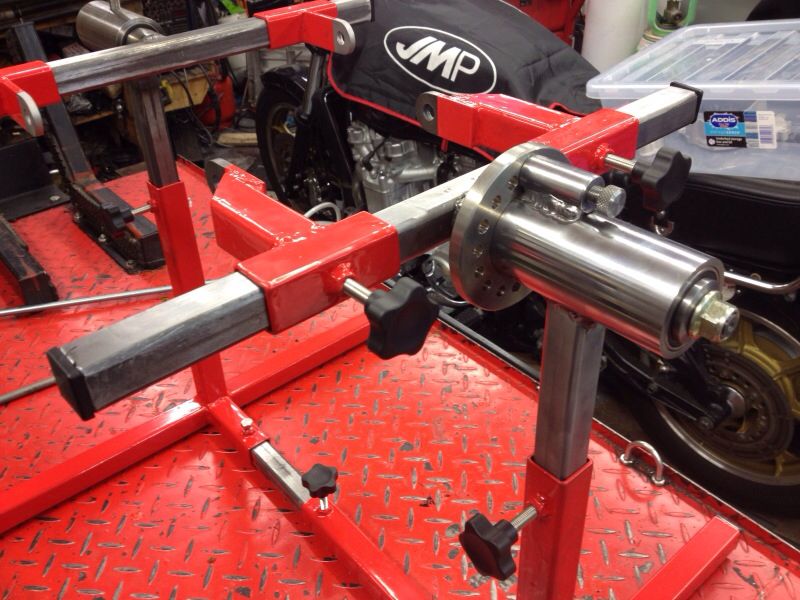

The head will have to be skimmed in the new year. I was going to get the engineers to recut the valve seats, but I managed to borrow a seat cutting kit from a friend to do an XS650 engine I'm working on, and decided to cut the seats on the GPZ motor while I was at it.

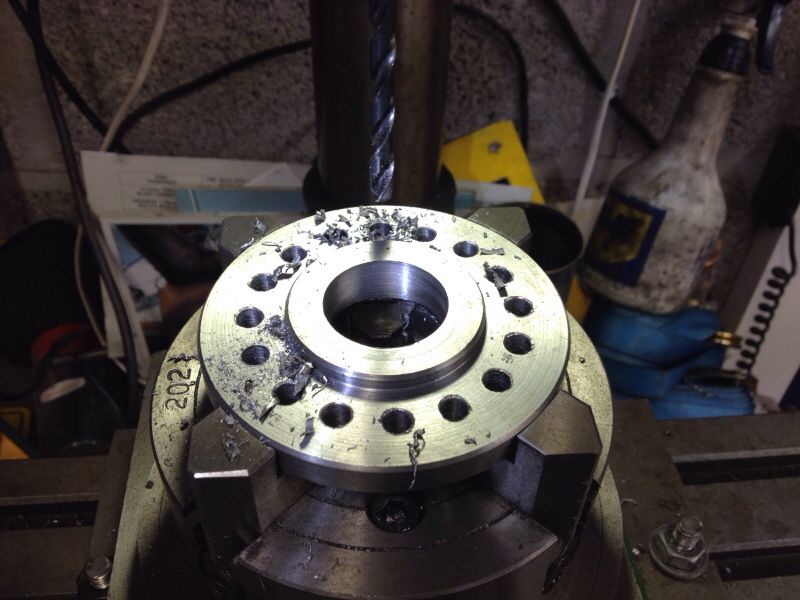

It's not so hard really, you tighten the mandrel in the guide, slide the cutter down the mandrel and basically turn it to cut until it's clean again. The hardest part was machining a precise sleeve as the mandrel small enough for the guide was too small for the cutter head.

And here's the freshly cut inlet seat

I intend to contact the makers of the valve face cutting tools, with a view to adding them to the list of wonderful shiny things available from Biker's Toolbox

In the not too dim and distant I will be painting the engine bits. I'm pretty sure that the outer cases eg alternator, clutch cover etc are all gloss black. Does anyone know whether the crank cases, barrels, and head are also gloss or are they satin?