Page 6 of 8

Posted: Wed Aug 10, 2016 7:06 pm

Author: swampy

Ok ok so I will get if done then Ginger. PS them ports do look trick!

Zed from what you have written I shall interpret that as 'just get it done and pay the man' or 'have a go yourself then buy a new head'.

Oh god whats next Andrews 3sx or web 110' cams?!

Posted: Wed Aug 10, 2016 8:52 pm

Author: tlc

Not that I have any experience of hotter cams but the stock unitrak cams are darned good.

I love the smooth power delivery on mine.

Intoxicating.

Posted: Wed Aug 10, 2016 9:15 pm

Author: swampy

well I'm at new cozzie 1170 pistons 10.5 cr. New A.P.E valves. springs, , guides, seals, cam journals, adjustable cam sprockets and a new cam chain. ( getting) seats re-cut and ports flowed. So a set of Web 110' cams that are readily available seem like the in for a penny in for a pound solution to me.

And that's just the top end!

Anyone with better tuning, engine building knowledge than I have (not a lot) feel free to jump in!

Posted: Wed Aug 10, 2016 9:31 pm

Author: slappa13

I use webcam 110 395 lift cams, they deliver a nice spread of power

Posted: Wed Aug 10, 2016 9:51 pm

Author: swampy

yep Im thinking of a set of those from dynoman In the USA at £385 before duty is added on. Or a set of Andrews 3sx from Jo Hooper at a similar price.

Anyone else?

Posted: Thu Aug 11, 2016 6:10 am

Author: Ginger Bear

I have 3x supplied by Joe Hooper (Excellent service).

Headwork done by Buzzard, who can be found on this forum

Posted: Thu Aug 11, 2016 9:36 am

Author: neilbarrett

while the parts are there id go the whole hog .match the inlet rubbers your gunna use as well.the material of cosworth pistons is meant to v good

Posted: Thu Aug 11, 2016 3:29 pm

Author: swampy

Hi Neil i have new genuine inlet rubbers, by matching them do you mean removing any spurious material left of from the moulding process.

Posted: Thu Aug 11, 2016 3:40 pm

Author: Ginger Bear

Diameter of the inlet rubber will be bigger than the diameter of the inlet on the head. Ideally you'll match the head to the diameter of the inlet rubbers.

Posted: Thu Aug 11, 2016 4:22 pm

Author: swampy

Ahh i see!

Posted: Thu Aug 11, 2016 7:15 pm

Author: chrisu

Ginger Bear wrote:I have 3x supplied by Joe Hooper (Excellent service).

Headwork done by Buzzard, who can be found on this forum

Dave (Buzzard) recommended Andrew 3X cams to me too but only if big bore and higher compression

Posted: Fri Oct 14, 2016 6:39 pm

Author: swampy

Not posted for a while. So heres an update.

Cleaned and cleaned the cases but could not shift old paint and over spray. So took em down too I Cleenz Machines as the owner is a classic bike nut.

Got em back and spent 5 hours masking them for paint today.

[img]

[img]http://i1244.photobucket.com/albums/gg574/paulkemp2/Mobile%20Uploads/20161014_133255_zpstqy9bdpc.jpg[/img][/img]

And here is the top case ready for paint.

The head is back with the ports matched, new guides fitted and seats cut for the APE valves. Along with the barrels bored to match the 1170 Cosworth pistons. All work being done by Roger Upperton.

Photos to follow.

Crank is also back from Chris Applebe after being stripped cleaned rebuilt with new mains and big ends then welded and balanced.

So its all systems go now on getting it all rebuilt.

Posted: Wed Jan 25, 2017 1:41 pm

Author: swampy

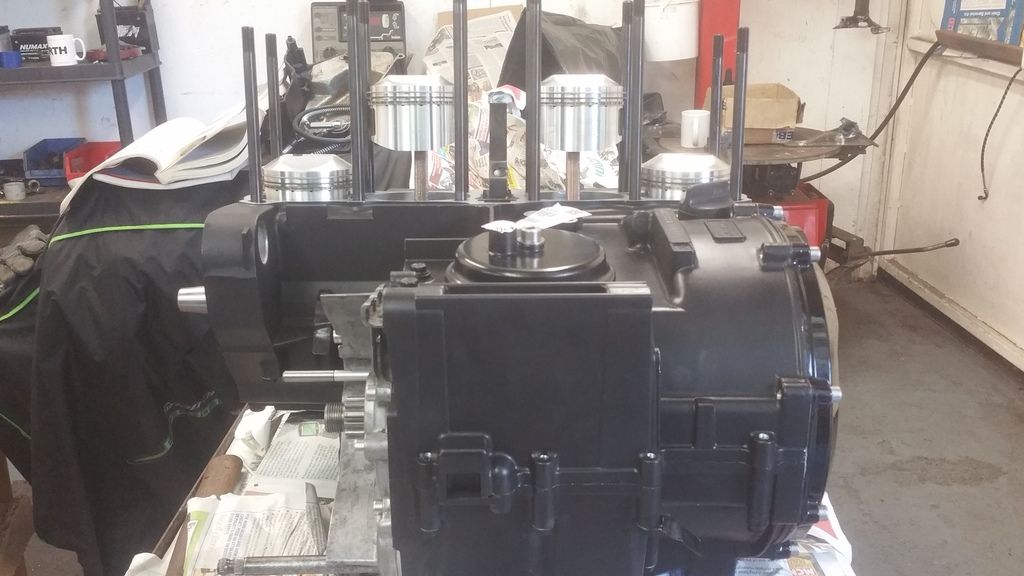

Ok project had wait for a while but new progress has been made.

Cases painted

[img]

[img]http://i1244.photobucket.com/albums/gg574/paulkemp2/Mobile%20Uploads/20161104_131001_zpsaxyvm4gy.jpg[/img][/img]

Rebuilt crank with new big ends and mains ready to go in

[img]

[img]http://i1244.photobucket.com/albums/gg574/paulkemp2/Mobile%20Uploads/20160708_113015_zpso5wnuvcx.jpg[/img]

Rebuilt gear box with new 2nd gear on 1st and 2nd shaft and new bearings all round.

[/img]

[[/img]

Posted: Wed Jan 25, 2017 1:49 pm

Author: swampy

Posted: Wed Jan 25, 2017 2:57 pm

Author: Julian_Boolean

Very nice