Page 2 of 6

Re: Harris Build

Posted: Sun Sep 23, 2018 4:26 pm

Author: cakeman

Soooooo, it appears this engine will be two steps forward and one step back. I'm happy with the finish on the engine so next was to remove the rocker cover to prep for paint, while the cover was off I thought I'd check the cam cap bolts as a couple looked a bit suspect as they didn't match the others, the result was that three of the bolts are stripped

so it looks like cams out and insert time again

At this rate there'll be no original threads left in this lump. It starting to make me doubt this engine

Re: Harris Build

Posted: Mon Sep 24, 2018 5:06 am

Author: KWACKERZ1

The two bolts are slightly longer than the std ones as the top of the threads were weak. Using slightly longer ones enabled me to pick up the bottom good threads torque everything down and still leave the option to helicoil them at a later date.

I guess it worked as several days at Spa multiple cbt days with no problem. So should be ok for abit of posing around on road

Sadly most zed engines have some weak threads as they are 30 year old.

Re: Harris Build

Posted: Mon Sep 24, 2018 6:22 am

Author: martinz1000r

The metal that is used in cylinder heads of this vintage is similar to cheese. It’s not helped by probably everyone that’s ever removed the cams winding the bolts down against the spring resistance from the valves springs. From personal experience you are really lucky if you don’t have a buggered thread. Don’t bother with helicoils as they can pull out leaving you with a bigger issue. Recommend you hold the cams down by wrapping a ratchet strap round them and the motor so they sit properly and then bolt down the cam caps. If a slightly longer bolt will catch then use it

Re: Harris Build

Posted: Mon Sep 24, 2018 7:29 am

Author: cakeman

martinz1000r wrote:The metal that is used in cylinder heads of this vintage is similar to cheese. It’s not helped by probably everyone that’s ever removed the cams winding the bolts down against the spring resistance from the valves springs. From personal experience you are really lucky if you don’t have a buggered thread. Don’t bother with helicoils as they can pull out leaving you with a bigger issue. Recommend you hold the cams down by wrapping a ratchet strap round them and the motor so they sit properly and then bolt down the cam caps. If a slightly longer bolt will catch then use it

Good tip regarding holding the cams in place with straps, cheers.

Managed to sort one of the bolts as it was the bolt that was stripped and not the thread in the hole so I’m assuming (without removing the cam cap) that it may have a helicoil already. The other two damaged threads are too far gone so unfortunately I’ll have to try using inserts as one of the bolts was only finger tight. On another subject one of the long m6 crankcase bolts was stripped and I managed to repair this by tapping it out to 1/4” unf and replacing it with the correct length unf bolt and it torqued down a treat. Onwards and upwards lol.

Re: Harris Build

Posted: Mon Sep 24, 2018 6:08 pm

Author: Al

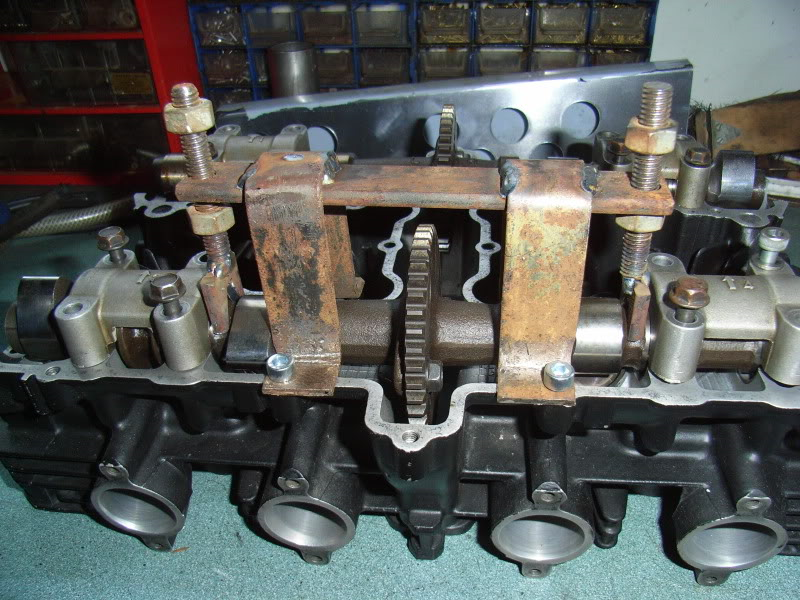

Ratchet straps are good, Debbens use a modified G clamp, i made this from scrap and its fine.

I usually end up doing a couple of those threads each winter. Thought i would have done them all by now.

- Frame.png (980.58 KiB) Viewed 7306 times

- Frame 2.png (1.02 MiB) Viewed 7306 times

AL

Re: Harris Build

Posted: Wed Sep 26, 2018 7:18 pm

Author: cakeman

I've ended up removing the cylinder head

Dynodave came round tonight to put the inserts in the cam bearing caps for me and as we removed the caps it transpires that there are already five inserts fitted, three of which are stripped and at least 4 helicoils of which 2 are no good plus under one of the inserts is the remains of a broken bolt which means that instead of the hole being able to accept a 40mm bolt it can only take a 30mm bolt, also 4 of the cam bearing shells are really badly scored and need replacing. Looks like it may be more cost effective to replace the head....Project has now ground to a halt unfortunately

Re: Harris Build

Posted: Wed Sep 26, 2018 7:34 pm

Author: Coose

That sounds very salvageable and not to be unexpected of a bike that age that's had previous work done.

The insert and bolt issues can easily be resolved, and the cam bearings do wear and aren't that expensive - the pattern ones are fine.

Re: Harris Build

Posted: Wed Sep 26, 2018 7:42 pm

Author: cakeman

Coose wrote:That sounds very salvageable and not to be unexpected of a bike that age that's had previous work done.

The insert and bolt issues can easily be resolved, and the cam bearings do wear and aren't that expensive - the pattern ones are fine.

If you know of anybody who can repair the head it would be greatly appreciated mate. Some of the m6 holes have already been drilled out to 9mm to take the inserts that have been fitted so there isn't much meat left around them.

The shells aren't just worn, there are big gouges in them but I've found a full set on eBay for just under a ton.

Re: Harris Build

Posted: Wed Sep 26, 2018 9:20 pm

Author: Coose

Speak to Dave at Saisei (Zedhead on here) for your cam bearings and any other consumables (gaskets etc.), he'll see you right.

The snapped bolt can be drilled out. Assuming that Timeserts have been fitted, what has stripped - the internal thread or has the sert pulled out of the head? Can an insert be fitted further into the hole and a longer bolt used? Don't write it off just yet, particularly if the head is Unitrak...

Re: Harris Build

Posted: Wed Sep 26, 2018 10:40 pm

Author: cakeman

Coose wrote:Speak to Dave at Saisei (Zedhead on here) for your cam bearings and any other consumables (gaskets etc.), he'll see you right.

The snapped bolt can be drilled out. Assuming that Timeserts have been fitted, what has stripped - the internal thread or has the sert pulled out of the head? Can an insert be fitted further into the hole and a longer bolt used? Don't write it off just yet, particularly if the head is Unitrak...

Cheers for that.

Unfortunately two of the inserts were fitted almost at the bottom of the hole as far as I can see and have pulled out of the head. Not sure if the head is Unitrak or B2 (how do you tell?) The snapped bolt was underneath the other insert, two of the helocoils are just mangled. The inserts are like a timesert but have a slot across the top so they can be screwed in with a screwdriver.

Re: Harris Build

Posted: Thu Sep 27, 2018 5:58 am

Author: Ginger Bear

Unitrak head will have a boss on the rear by No.1 inlet for a temp sensor.

Big Sert's may help, but will depend if the hole is doweled or not. Buying direct from the US worked out cheaper for me.

Snapped bolts could be spark eroded by a good auto engineer.

Great project!

Re: Harris Build

Posted: Thu Sep 27, 2018 6:30 am

Author: cakeman

Ginger Bear wrote:Unitrak head will have a boss on the rear by No.1 inlet for a temp sensor.

Big Sert's may help, but will depend if the hole is doweled or not. Buying direct from the US worked out cheaper for me.

Snapped bolts could be spark eroded by a good auto engineer.

Great project!

Looks like it’s a Unitrak head then. Unfortunately two of the damaged threads with the inserts are the dowelled ones and are already 9mm across the top of the hole. Looks like I’ll be looking for a new head.

Re: Harris Build

Posted: Thu Sep 27, 2018 8:53 pm

Author: Al

You could try and give Ray / Steve Debben a ring and see if they can do anything with the threads. They really do know what they are doing and if it can be fixed they will be able to do it. Not seen anything they couldn't fix as yet. 01425 474628

AL

Re: Harris Build

Posted: Thu Sep 27, 2018 9:58 pm

Author: cakeman

Al wrote:You could try and give Ray / Steve Debben a ring and see if they can do anything with the threads. They really do know what they are doing and if it can be fixed they will be able to do it. Not seen anything they couldn't fix as yet. 01425 474628

AL

Cheers Al I'll give them a call tomorrow and see if they can help. The limiting factor for me will be the cost unfortunately, balancing the cost of repair against the cost of picking up a new head, I need to budget for new cam bearing shells and on top of that will be the cost of the thread repairs, it may make more sense to try and track down a new head as I can only afford to spend a couple of hundred fixing it. To be honest I didn't bank on this much trouble with the engine when I initially saw the spec.....probably a bit naive of me really

I assume I can use either a Unitrak head or a B2 head ? Are there any other's that are compatible?

Re: Harris Build

Posted: Thu Sep 27, 2018 10:21 pm

Author: zed1015

cakeman wrote:I assume I can use either a Unitrak head or a B2 head ? Are there any other's that are compatible?

No. Unitrack head has different (steeper) exhaust valve angles to the B2 and all the others.

If you have a unitrack bottom end (18mm gudgeon pins) you need to use the Uni head unless you want to get into modifying the exhaust valve pockets on the pistons.

so it looks like cams out and insert time again

so it looks like cams out and insert time again  At this rate there'll be no original threads left in this lump. It starting to make me doubt this engine

At this rate there'll be no original threads left in this lump. It starting to make me doubt this engine