#47 PostAuthor: Philippe » Wed Jun 12, 2019 2:56 pm

Hi Simonic

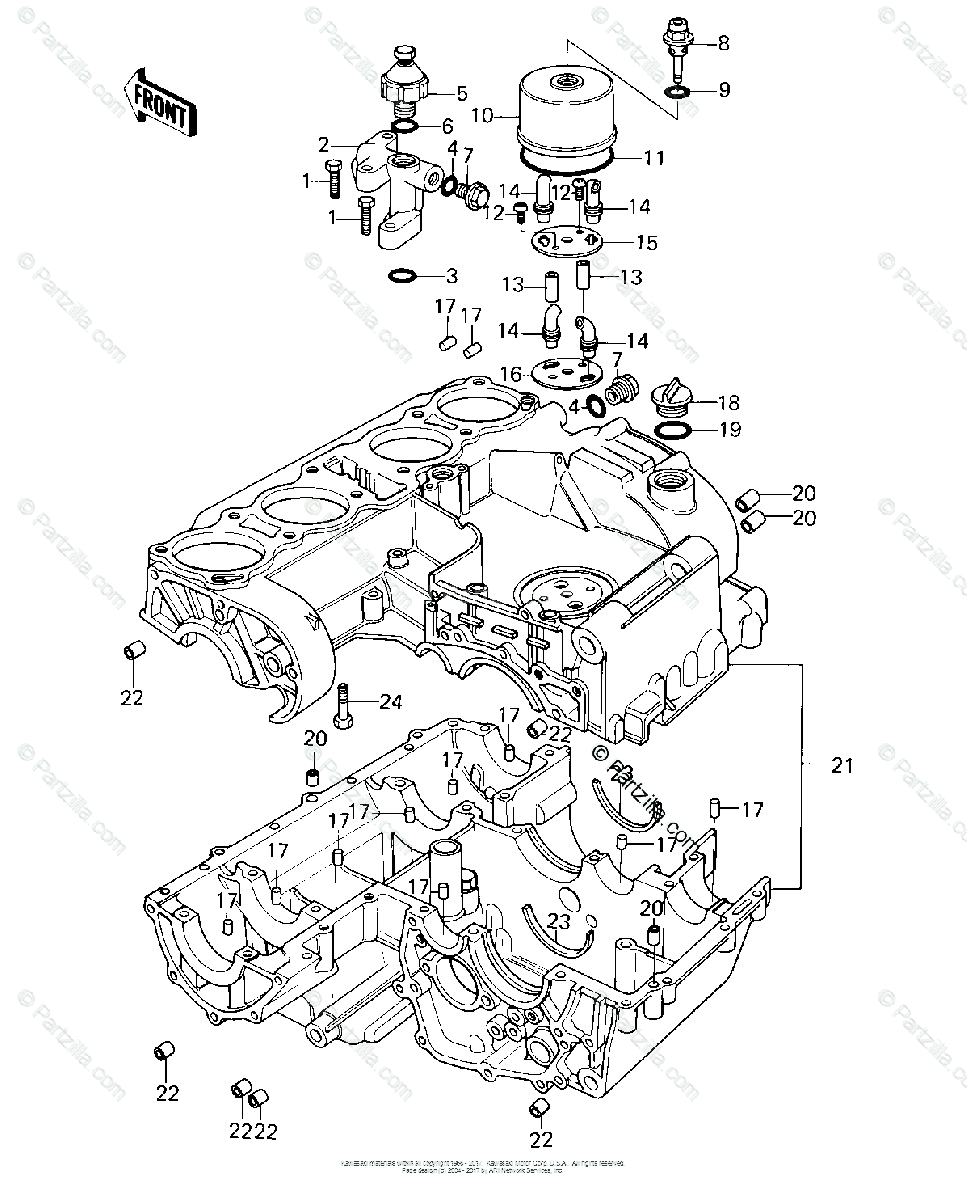

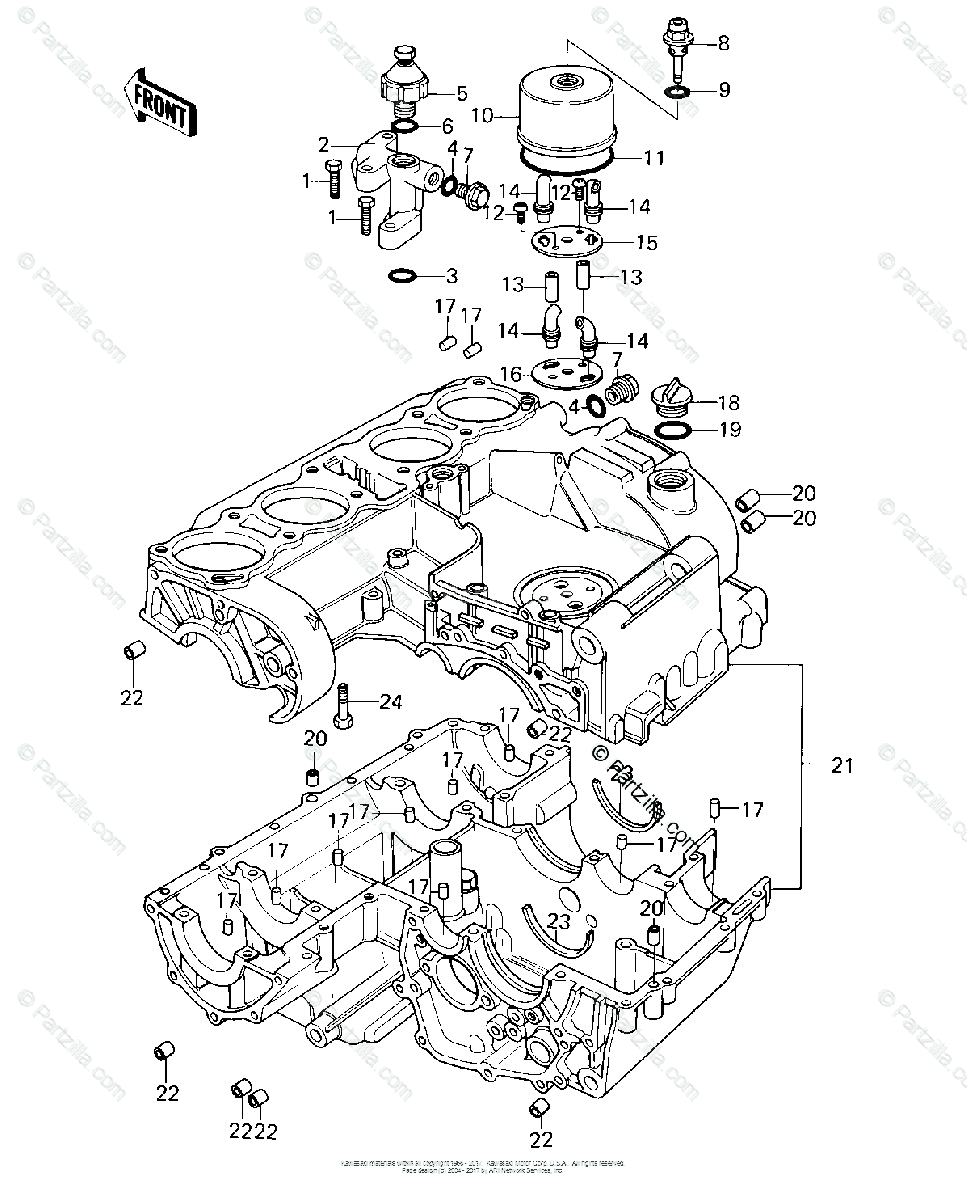

that "little fellow" can come from a few different places: the pin that keeps the kickstarter shaft in place, one of the five pins of the cranckshaft, one of the pins that keeps the cages of the roller bearings of the input or the output shaft in place.

These are all situated in the upper cranckcase. If one of them dropped out, take a dowel, place it on the side of the gap where the pin should be and give a gentle tap on the dowel with a hammer. Put the pin back in the hole afterwards and make sure it stays out about 5 mm.

As far as the broken output shaft is concerned: don't mind, it's common. It's one of the weak spots of the ST.

If you can find a complete shaft, replace the one in your engine, if not, find someone who can work with a lathe.

Let him drill a hole in the shaft, make a thread in it (M10) and use an M10 allen bolt to secure the coupling of the drive shaft. (Take a look at how it's done in one of my previous projects; I think there's a picture)

Your ST will also work without the nut in place. The coupling is held in place by the strong spring.

Good luck!

GrtZ

Philippe

the differences between a little boy and an adult man is the price and size of their toys!